QMG0324: MP3003CNC 10 Foot x 140 Ton Hydraulic Press Brake, New 350 EDV 14" Manual Cold Saw, US168125.X7-24IN: SYSTEM 16 (x2) 3'x4' Imperial Series Welding Table Special 2024 Bundle

QMG0324: MP3003CNC 10 Foot x 140 Ton Hydraulic Press Brake, New 350 EDV 14" Manual Cold Saw, US168125.X7-24IN: SYSTEM 16 (x2) 3'x4' Imperial Series Welding Table Special 2024 Bundle

Order Today: BUNDLE IS VALID UNTIL 3/31/24

Ready to place an order, or do you have any questions? Call us at (704) 703-9400

TAKE YOUR FABRICATION TO A WHOLE NEW LEVEL

Our New Fabrication Bundle is a great way to improve your metalworking and fabrication. Our MP Series Hydraulic Press Brakes take sheet metal bending to a whole new level, offering outstanding efficiency and precision. The NEW 350 EDV Cold Saw is a game changer for any DIY enthusiast or professional, cutting up to 4-1/4" Round Tube. The Siegmund US168125.X7-24IN: System 16 (x2) 3'x4' Imperial Series Welding Table 88 Piece Bundle ensures precision and quality in every project. Pair it with our high-performance welding Fabricating Accessories, offering exceptional control and durability for all materials. Together, these three form an unbeatable combination that ensures your projects are always a cut above the rest.

BUNDLE VALID UNTIL 1/31/2024

ASK YOUR SALES REP. FOR bundle no. qmG0324

WHAT IS INCLUDED IN THE QMG0324 FABRICATOR BUNDLE

MP3003CNC: 10 Foot x 140 Ton Hydraulic Press Brake

US168125.X7-24IN: System 16 (X2) 3'X4' Imperial (Inch) Welding Table And 88 Piece Bundle

NEW 350 EDV: 14" Manual, Pivot-Style Cold Saw

MP3003CNC: 10’ x 140 TON HYDRAULIC PRESS BRAKE

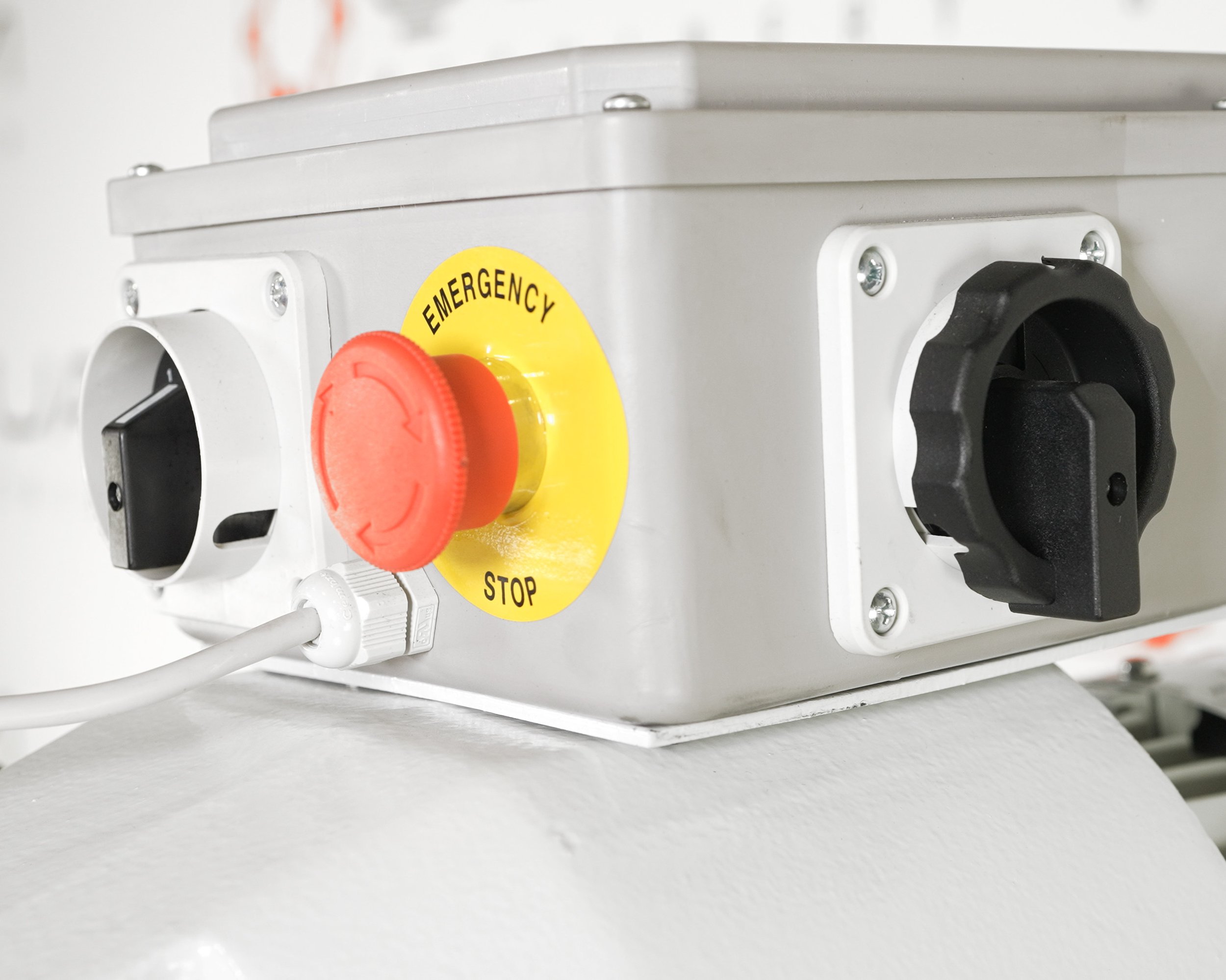

Among the elements that make the new Nargesa CNC hydraulic press brakes ideal for the sheet metalwork industry, we highlight the following: the adaptive electronic pressure control system which ensures the force required for each operation; the chassis bending electronic compensator which gives optimum bending precision with different sheet metal lengths; the micrometric resolution optical encoder which permits perfect positioning of the vertical axis of bending; the sophisticated electronic compensation system for hydraulic oil temperature, which can be configured using software to offer repeat bending at different working temperatures; the self-monitoring safety hydraulic system contained in a single unit which provides manometer pressure information at all times with optics indication of the status of valves and sensors, transmitting movement to the vertical bending axis ensuring precision to within 0.01mm, and a servo motor driven back gauge with maximum precision recirculating ball screw guide which reduces X and R axis positioning error to less than 0.05 mm and the option for manual adjustment of the Z axis; and 2.0 connectivity for seamless LAN integration of machines via a 10/100 Mbit Ethernet connection for the remote control, management, diagnosis and update of machines. A full range of specifications is designed to provide maximum performance using technological components of the highest quality to make the operator’s job easier.

Technical Features:

Punch working speed: 0.26"/s. Inner folding length: 106.29" / 8'-10"

Return speed of the punch: 1.70"/s. Total folding length: 123" / 10'-3"

Lowering speed of the punch: 1.0"/s. Back gauge displacement: 23.6"

Maximum punch displacement: 6.29" Weight: 20,100 lbs.

Motor power: 9.5 KW / 12 HP. Dimensions: 147" x 64" x 110"

Three phase power: 230V or 480V The machine is delivered completely assembled.

Hydraulic Power: 140 Tons

Fitted with high-specification CNC control, the operation of these complex machines is now easier and more intuitive than ever before. It's color, high-resolution touchscreen graphics interface and powerful CPU enable the most complicated bending operations to be processed effortlessly.The complex algorithms processed by the CNC control enable the total worked length of the sheet metal to be obtained accurately according to the bending program. Furthermore, bending sequence management makes it possible to select the most suitable option for producing each piece, ensuring greatest ease for user who also has invaluable help in the form of the efficient 2-D visual bending simulator, which displays the positioning of the sheet metal in the press brake during each stage of the process, in addition to graphics display of the progress of different bending operations being performed.

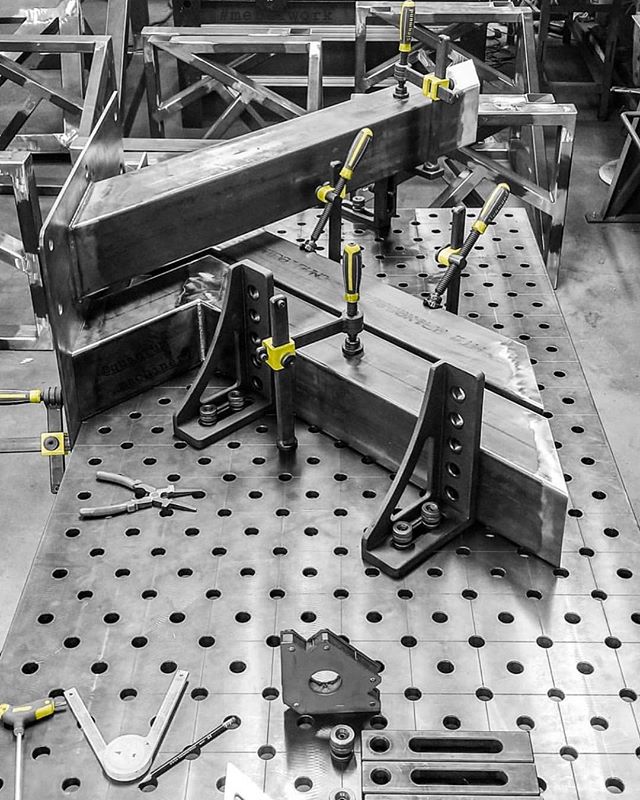

US168125.X7-24IN: System 16 (X2) 3'X4' Imperial 8.7 Series (Inch) Welding Table 88 Piece Bundle

Items Included in Bundle

#US168125.X7-24IN

Welding Table Specs and Features:

Overall Tabletop Size: 3' x4' (Both Tables with Squares: 3'x10')

Borehole Diameter: Ø 16mm (5/8")

Welding Table Series: Professional Extreme 8.7 Series

Welding Table Material Thickness: Approx. 7/16" to 1/2"

Welding Table Material Type and Finish: Professional Extreme 8.7 Hardened Tool Steel, Plasma Nitrided and BAR-Coated

Table Surface Hardness: 450-850 Vickers

Official Siegmund Welding Table Part No.: US160025.X7

Maximum Weight Load Per Table: 8,800 lbs. (Based on Even Distribution with Standard Legs)

Approximate Weight Per Table: 486 lbs.

Boreholes on the Surface are a 2"x2" Inch Grid Configuration.

Boreholes have a diameter of 16mm (5/8"), Boreholes have a 1/16" Radius.

Radius 1/10" on the table edges and 1/4" on the corners.

Height of table side is 3-15/16", Borehole in Diagonal Grid.

INCH Scale Engraved on the Surface.

Bottom of Structure has Reinforced Ribbing.

NEW 350 EDV: 14" Manual, Pivot-Style Cold Saw

TECHNICAL DATA & FEATURES:

Movable Cutting Head: From 45° Left up to 45° Right.

Double-Hinged Pin with Eccentric Bush.

Reduction Unit in Oil Bath.

Double-Quick Locking Vice.

Coolant Filter.

Jet Separation System to keep the Blade Oiled.

Sliding Counter-Vice for Longitudinal Cutting.

24V Low Voltage Installation withhold-to-run Head Control Knob.

0.09 kW Power-Driven Pump for Band Cooling.

Blade Size: 350 x 2.5 x 32mm Bore HSS Blade

Maximum Vice Opening: 4.7” (120mm)

Machine Weight: 510 lbs. (231 kg.)

2 Speeds: 40 - 80 R.P.M. (Saw can be equipped with Variable Speed Inverter)

Overall Dimensions: 4'-10"H x 3'-4"W x 3'-11"L or 58”H x 40”W x 47”L or 1,475mm H x 1,000mm W x 1,200mm L

This Saw Includes: the Pedestal/Stand, Bar Stop, Bar Support Arm, Instruction Manual, Service Tools & 1 HSS Cold Saw Blade.

MAXIMUM CUTTING CAPACITIES:

Solid Round

Straight Cut: 2.3"

45° Left Cut: 2.15"

45° Right Cut: 2.15"

Rectangular Tube

Straight Cut: 3.15"H x 4.7"W

45° Left Cut: 3.15"H x 3.15"W

45° Right Cut: 3.15"H x 3.15"W

Round Tube

Straight Cut: 4.3"

45° Left Cut: 3.15"

45° Right Cut: 3.15"

Square Tube

Straight Cut: 4"

45° Left Cut: 3.15"

45° Right Cut: 3.15"