In this video, you will find many of the tremendous benefits with choosing our Nargesa "H Series" Propane Gas Forge Furnaces.

12 EXTREMELY CRITICAL KEY POINTS ON WHAT MAKES OUR "H SERIES" GAS FORGE FURNACES BETTER AND MORE SUPERIOR THAN ANY OTHER GAS FORGE FURNACE ON THE MARKET

Savings with Gas Consumption. Our Propane Gas Forge Furnaces consume less than a 1/4 of the propane used by other furnaces of this type.

Extremely Safe, Auto Burner Ignition. Automatic Electronic Ignition ensures that the operator does not need to put their hands inside of the combustion chamber to ignite the furnace.

100% Natural & 100% Recyclable Combustion Chamber. The insulation of the combustion chamber is made up of a 100% Natural & 100% Recyclable material, called Vermiculite. The compacted Vermiculite is not harmful to your health or the environment at all - unlike all other gas forge furnaces in the market, which are made up of glass fibers & ceramics, which are extremely harmful to you.

Dual Insulation Layer for Heat Effeciency. The Dual Layer of Insulation increases the caloric heating value of our Nargesa furnaces; allowing the furnace to reach temperatures of up to 2370°F / 1300°C inside - while on the outside, the temperature ranges from 86-140°F / 30-60°C

There is no fuel loss. All of the gas that enters into the combustion chamber is burned out completely, thanks to Nargesa's patented design of the burners, which have been completely created & manufactured by Nargesa.

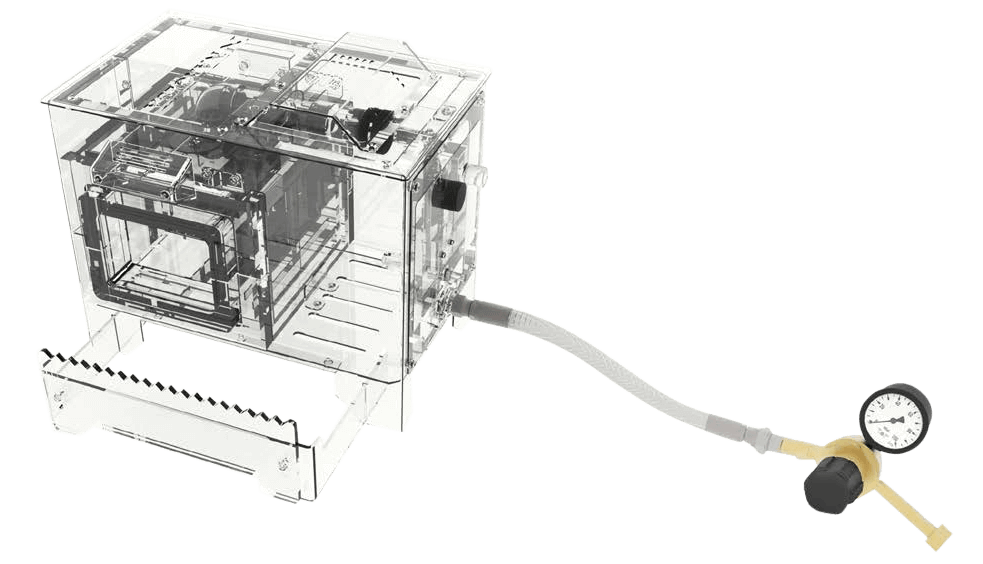

Stainless Steel, Highly-Durable Gas Hose. Our Gas Forge Furnaces are Equipped with a High-Strength, Extremely Durable Stainless Steel Gas Hose. Generally, conventional Gas Hoses have an expiration date & they must be replaced periodically. Our Stainless Steel Hose never expires and never have to be replaced. Our Stainless Steel Hoses are also Shock and Fire/Heat Resistant.

Protected Components. All components are contained within the structured enclosure to eliminate the possibility of damaging any parts, preventing any gas leaks.

Large Round Bar Capacity. Our furnaces can heat up round bars up to 3-1/8" (80mm) diameter. There is also a quick-release removable rear door to heat the middle sections of longer pieces.

Interchangeable Material Support. Our furnaces are equipped with an Auxiliary Support for the parts being heated. The Support can be quickly adjusted in length and height and has pyramidal teeth to prevent material displacement. You can remove the support and place it in front of whichever opening of the furnace you would like.

Next to no Carbon Monoxide Emission Release. Other furnaces have a Carbon Monoxide Emission release of 2%, while our H Series Forge Furnaces have a Carbon Monoxide Emission release of 0.002%, enabling our furnaces to be harmless to your health & the environment.

No Possible Leaks. The High Pressure Thermal Couple Safety Valve closes the gas flow when the combustion chamber cools off, due to an anomaly - ensuring that there are no possible leaks.

Anti-Return Valve prevents flame from entering into Tank. A Safety, Anti-Return Valve regulates the direction of gas flow, preventing the flame from going back into the cylinder tank. The pressure regulator is equipped with a built-in pressure gauge, allowing the operator to adjust the gas pressure very accurately.

THE NARGESA H SERIES TECHNICAL FEATURES:

Insulation of Vermiculite:

Double insulation of compacted vermiculite, to avoid head loss. Insulating flange in the material inlets to keep the heat inside the combustion chamber.

Removable Rear Door:

To work in the center of the iron bars. The doors are installed without using heavy-duty tools.

Integrated Bar Support, Adjustable to Different Lengths of Material:

It's shape prevents the material from sliding/slipping laterally. There is an option to place the bar support on either of the 2 entries.

Painting:

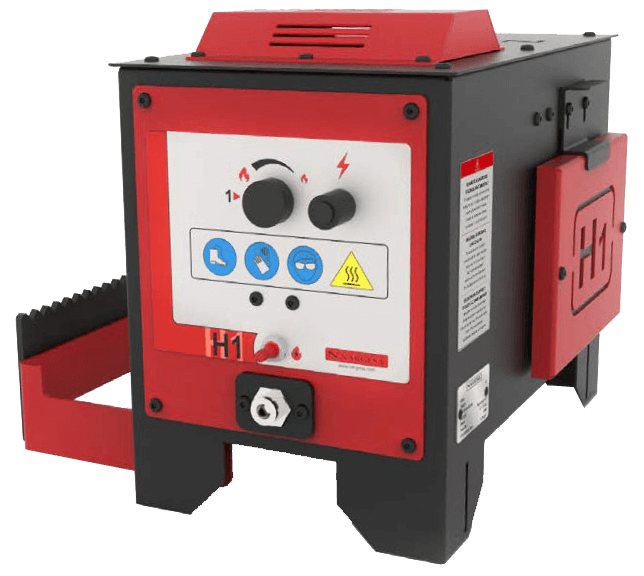

The Furnace is covered with heat paint to protect the operator.

Air Flow Regulator:

To adjust the size to the different altitudes. Depending on the work place of the furnace and its altitude regarding the sea, the air flow for the mixture of gas and marine air will be regulated, the sustainability for a good combustion.

Needle Flow Regulation Valve:

Allow the accurate regulation of gas flow.

Gas Hose made of Stainless Steel:

This characteristic prevents it from collapsing and burning. This hose does not expire, so it is not necessary to replace it.

Precision Pressure Regulator with Built-In Pressure Gauge:

Allows to adjust the gas pressure more precisely.

Gas Valve:

The Control panel has got one valve for the opening of the gas entrance to the Burner. The operator controls them in order to obtain more on less gas flow.

Electronic Switching:

Is the one that activates the spark plug and generates the spark to light up the Burner.

Thermocouple Push-Button:

In the one that opens the valve the get the thermocouple activated. This valve opens the path to the gas valves.

Main Advantages of using a Propane Gas Furnace instead of a Conventional Carbon Forge:

SAFER: The H1 has new security systems for the operator. Fulfilling the regulation RD919/2006. (Certified by the Technological Center APPLUS, General Laboratory for Testing and Investigation.)

MORE EFFICIENT: Consume up to 75% less gas and reach a higher temperature than any oven in its category. (More than 2,400ºF / 1,300ºC)

RESPECTFUL OF THE ENVIRONMENT: Emissions below 0.002% of CO. Internal Vermiculite Coating, which is 100% natural and recyclable.

Fast reaching of working temperature.

It's clean and it does not produce harmful emissions for health.

Easy ignition.

Possibility of moving it to the working site.

Put simply, its simplicity, size, easy ignition and fast reaching of optimum working temperature, make it a very versatile furnace.

NOTE: This forge is equipped with a European regulator, customer is responsible for changing the regulator for U.S. use.

SAFETY OF THE OPERATOR

The safety of the operator is one of the main premises when designing all Nargesa machines. The H1 forging furnace has got all the necessary safety devices for the well-being of the operator that will handle it and it is according to the Regulation of appliances that use gas as fuel RD919 / 2006.

Automatic Electronic Ignition:

Prevents the operator from inserting his hands in the combustion chamber to turn on the gas. No tool is necessary to generate the spark.

Gas System Integrated in the Oven Structure:

The components were totally protected from impacts that could damage and cause leaks.

Insulation of the Combustion Chamber:

These elements are formed by a 100% natural material, compacted vermiculite, not harmful to health. 100% recyclable as it does not include glass fibers or ceramics.

Thermocouple Safety Valve:

This device closes the passage of the gas when the combustion chamber cools due to an anomaly, avoiding any possible leak.

Anti-Return Valve:

This valve regulates the direction of the gas flow preventing it from being addressed to the cylinder.

ENERGY EFFECIENT

Saving energy is another topic that our R & D department takes into account for the furnace.

Fuel Consumption:

The consumption of Nargesa furnaces has been reduced in a 75%, that is to say, it consumes 1/4 of the fuel used by the same furnaces in its category. With a LPG propane gas cylinder of 35Kg, the H1 Furnace will operate 100 hours.

Gas Losses:

There is no fuel, all the propane gas that enters the combustion chamber burns, without any sort of waste. This process has been possible due to the new burners, which have been designed and manufactured by Nargesa.

RESPECT FOR THE ENVIRONMENT

It is totally unfeasible to manufacture machinery and not to take into consideration the planet we inhabit.

NEW Generation of Insulating Material:

The insulating material of the combustion chamber, the compacted vermiculite, is a 100% recyclable material and does not generate waste, increasing the heating (thermic) power of the cavity, over 1300ºC.

CO Emissions:

The emissions emitted by the furnace are 0.002%. In normal environment this value is between 0 and 2. Certified by the General Laboratory of Tests and Investigations: APPLUS Technology Center.